Case Study

Silt control with Bubble Curtain in London

Construction, Infrastructure & DevelopmentClient

MWH Treatment on behalf of Thames Water

Location

New River, East London

Objective

Essential bank stabilisation works

Challenge

Pollution risks associated installing several hundred meters of steel sheet piles

The challenge

Essential bank stabilisation works on the New River in East London required the installation of several hundred metres of steel sheet piles as part of a vital maintenance programme.

This created a significant challenge in preventing silt pollution from travelling downstream. The project was critical to protect a key drinking water abstraction.

In-channel works such as dredging and bank stabilisation stirs up silt, leading directly to the suspension of sediments within the water column.

This can cause silt pollution downstream, directly impacting wildlife & habitat as well as being detrimental to water abstractions.

The solution

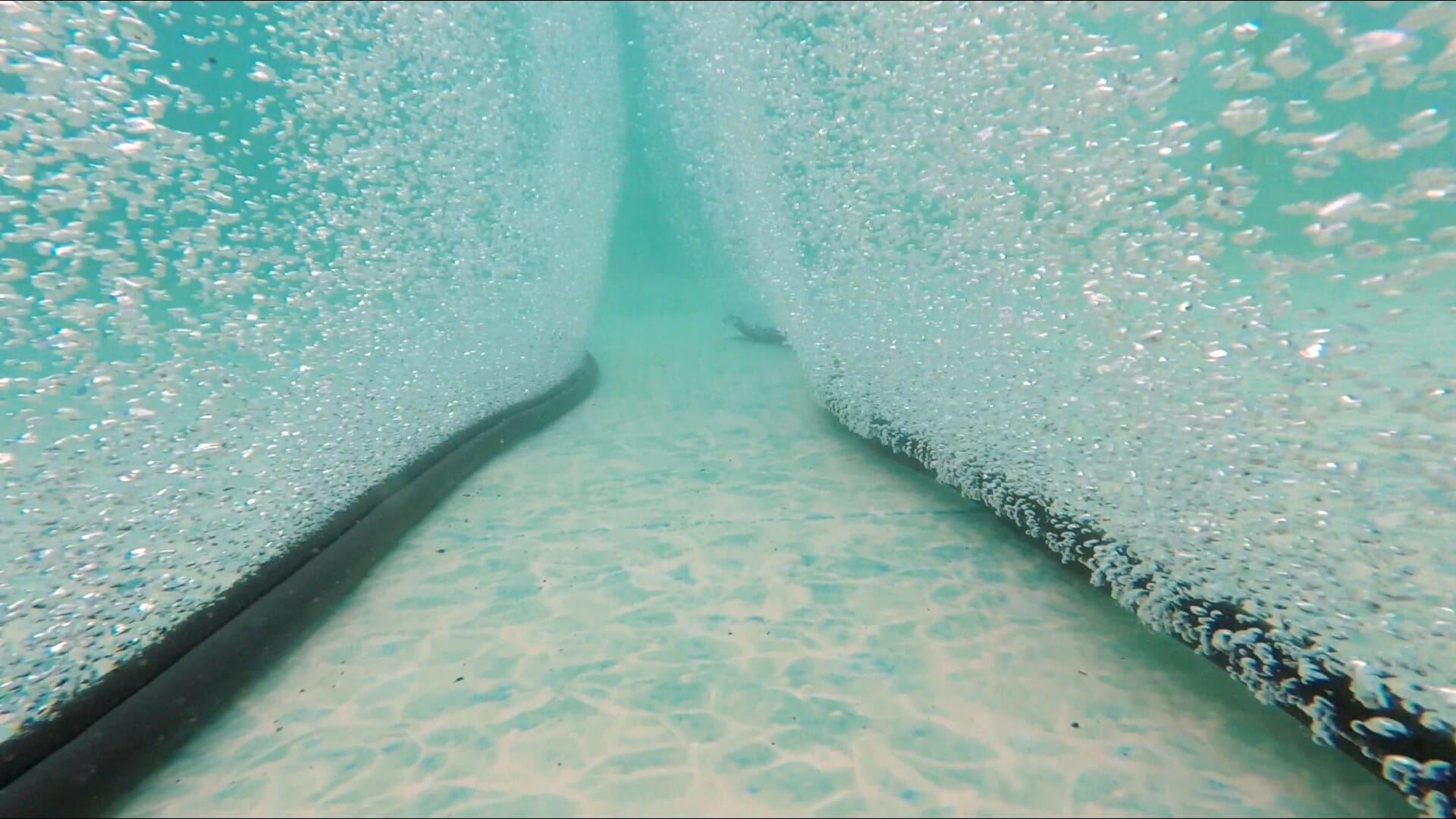

We were delighted to help them specify four lines of Bubble Tubing®, powered by a single, silenced compressor to create a bubble barrier that prevented the movement of silt downstream.

The river banks were too weak to support heavy, land-based plant so a floating piling rig was used to drive the new piles from the water.

The project had to be undertaken quickly and efficiently to minimise the risk of over-running and the potential to disturb roosting bats.

The bubble barrier was the ideal pollution control tool as it could be re-positioned quickly and easily to remain in front of the piling line and control the fine suspended particles generated from the activity.

As part of the bubble curtain package an oil free, silenced, electric compressor was supplied to provide compressed air to the bubble barrier, with no disturbance to local residents or risk to the environment.

The bubble barrier also aerated the water column, an added benefit that reduced the risk of low oxygen levels, often associated with muddy water impacting on the fish populations.

Excellent aerator

Increased dissolved oxygen levels reduce the risk of fish kills or harm to other aquatic life when construction is taking place in their environment.

Dual purpose technology

Bubble Curtains & Barriers have wide application ranging from underwater noise control to silt management, abstraction protection, inlet protection, litter and weed prevention and emergency aeration. They can be scaled to suit the length of the works being undertaken.

The results

Stops 90% of silt movement

Independent research undertaken by SEACAMS has shown Bubble Tubing® can control 90% of silt particles down to 63 microns.

Stops fine clayey silt from polluting waterways

This New River project demonstrates that smaller silt particles associated with London clay can be controlled in a low flow environment.

The products

Silt & Debris Bubble Barriers

- Controls sediment plumes, preventing silt and debris spreading in water

- Protects habitats by shielding sensitive aquatic life and ecosystems

- Creates a flexible silt control barrier that is designed to adapt to varying water depths

- Quick to deploy and remove without inhibiting navigation

Aeration Bubble Curtains

- Lightweight, modular design allows quick setup in urgent situations

- Fine microbubbles restore dissolved oxygen levels fast, stabilising water quality

- No submerged moving parts means low risk of mechanical failure and minimal maintenance under pressure

- Bubble aeration systems can be adapted to various water bodies or emergency site conditions

Litter & Weed Control Bubble Curtains

- Creates a dynamic barrier with rising bubbles blocking and redirecting floating debris

- Non-intrusive solution that allows fish passage and does not harm aquatic life

- Does not hinder navigation so vessels can cross without obstruction

- Low-maintenance & scalable and can be easily adapted for rivers, harbours, or industrial sites

Water Injection Dredging Bubble Curtains

- Enhances dredging efficiency by keeping fine sediments suspended and improving water injection flow

- Reduces resettling by preventing silt from quickly settling back onto the bed

- Cuts operational costs by minimising repeat dredging and optimising equipment use

- Non-intrusive,flexible and safe to use, making it easy to deploy in busy harbour environments