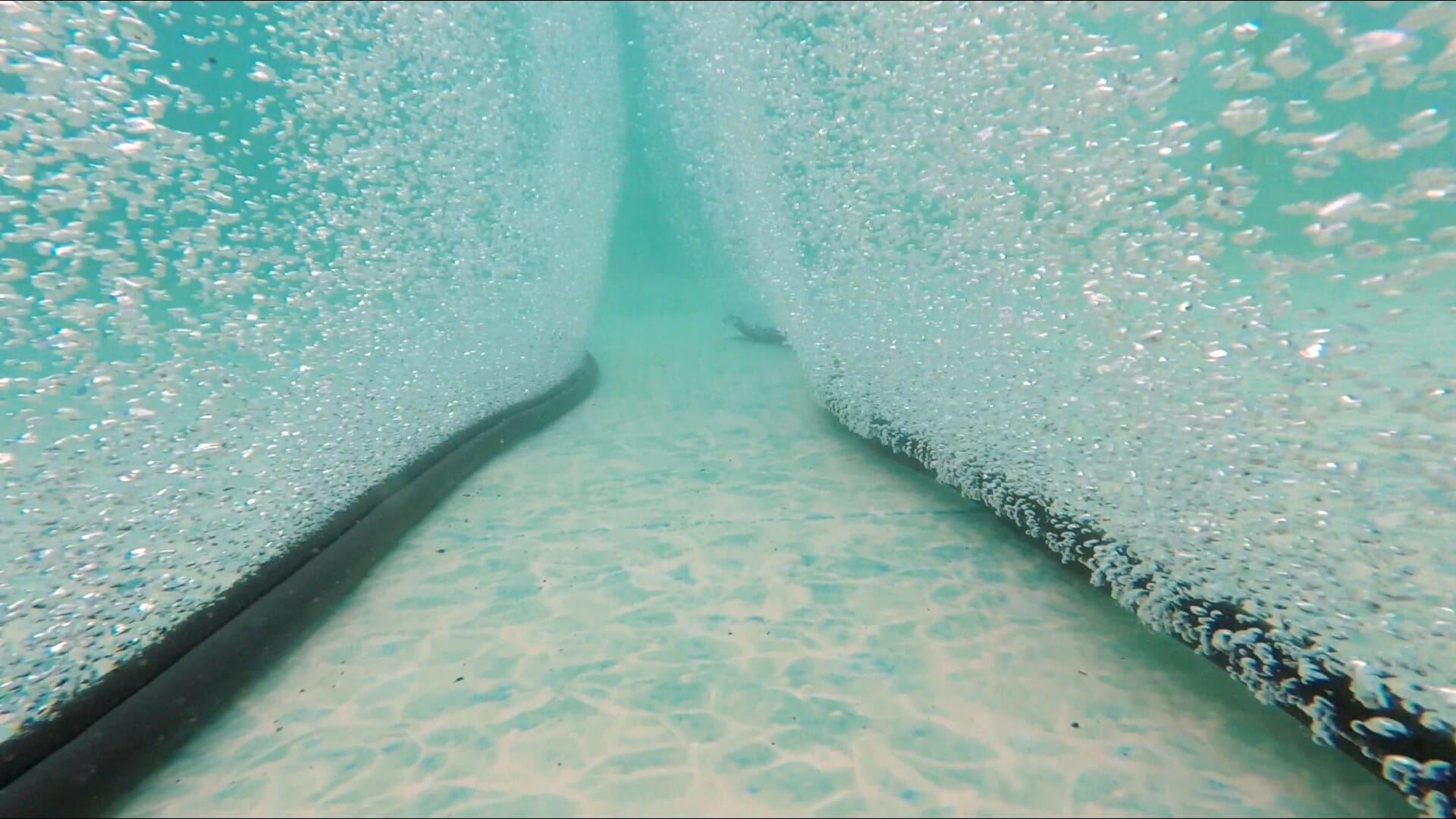

Bubble Curtains: A powerful solution, but don’t DIY

Bubble Curtains are ground-breaking technology for preventing and managing a wide range of pollutants.

When correctly engineered and adapted to local project conditions, Bubble Tubing® bubble curtains provide an effective solution for trapping sediment, aerating water, and preventing pollution from travelling downstream.

It can also be used to prevent sound pollution from under water works which can harm fish and other aquatic life.

Here at Frog Environmental, we have developed Bubble Tubing applications in the UK over the past decade. It is the most effective and energy-efficient solution that does not hinder ship, boat, canoe or fish passage. Here’s how it works:

-

Bubble Curtain engineering:

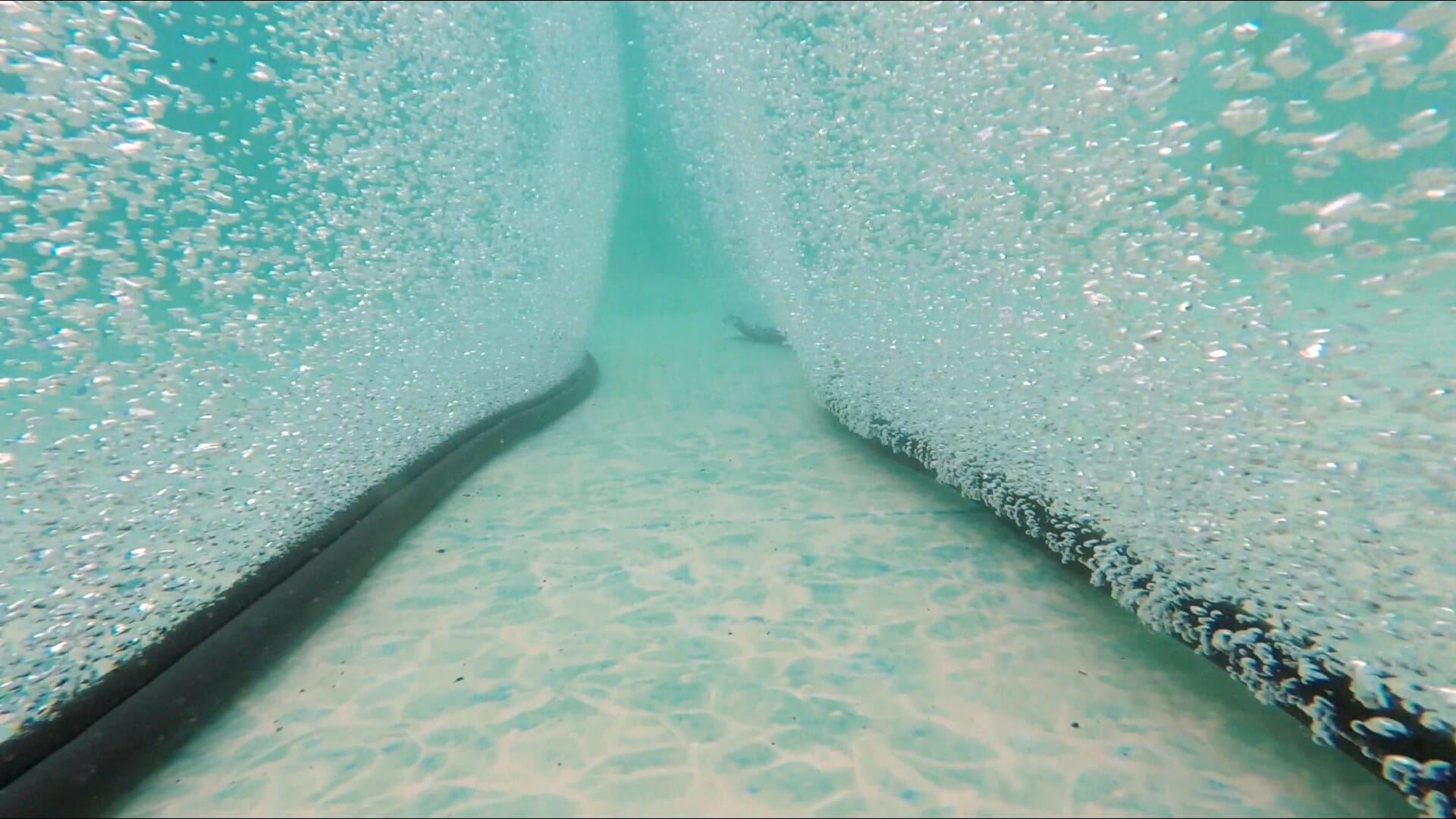

By pumping compressed air through a finely perforated tube on the waterway’s bottom, a bubble curtain is formed. These bubbles create an upward current. This holds back rubbish, silt and aerates the water body. Bubble Curtains have also demonstrated that they can be engineered to help reduce sound waves and vibrations underwater.

-

Strategic placement:

A bubble curtain or barrier can be placed across a water body such as a river or can be used to wrap an area of works to contain pollutants. They have been cleverly engineered and can be built to suit the length of site works, in some cases rather than wrapping a whole site area, the bubble curtain is used in stages and is moved as the works take place along a river wall, for example. Our technical team will help discuss options with you that works with your budget whilst achieving your environmental protection aims.

-

The power of micro bubbles:

We partnered with Swansea University to independently assess the effectiveness of our bubble curtains in preventing sediment from being dispersed downstream. The specially engineered pipes emit microbubbles, set to a specific size which is particularly effective at preventing the transportation of sediment in watercourses.

Why DIY bubble curtains are risky

Let us address the idea of making your own bubble curtains from plastic tubing. While it might seem like a cost-effective solution, there are several reasons why it’s not advisable:

Ineffectiveness: DIY bubble curtains lack the precision and engineering of professional systems. 20 years of R&D has been invested in this product and the exact placement and size of the holes that create the bubbles are of great importance to the effectiveness of a bubble curtain.

Without accurate design, validation modelling and experience gained by years working in this industry, they may not create the necessary upward current required to meet your project needs. Our technical team pride themselves on designing our clients with robust, cost-effective and low carbon solutions to negate environmental challenges.

Biofouling: Our tubing is self-cleaning and requires minimal maintenance. DIY systems are not, and will result is water ingress into the pipes which then encourage biofilm and algae to grow, which will then cause your DIY system to fail.

Efficiency: Our bubble curtains guarantee a very efficient oxygen transfer – research has shown its one of the best aerators – the larger drilled holes in DIY versions do not create the right consistency of microscopic holes to achieve guaranteed results.

Durability: Commercial bubble curtains, like Bubble Tubing®, are designed for longevity. DIY plastic tubing may degrade quickly, rendering your curtain ineffective and risking micro plastics being dispersed into the watercourse.

Safety: Bubble Tubing® is safe for fish and boat passage, while DIY curtains may harm aquatic life due to improper design.

What sets Bubble Tubing® apart?

For around a decade we have been the exclusive commercial UK supplier of Bubble Tubing®, collaborating closely with its creators, CanadianPond.ca Products Ltd.

Our bubble curtains, designed around Bubble Tubing® technology, offer several distinct advantages:

Technical expertise: Bubble Tubing® benefits from expert technical guidance and a process-driven design approach for silt pollution and sound control applications.

Safety and simplicity: It’s safe, controllable, and easy to deploy. Plus, it comes with a 5-year parts warranty.

Chemical resistance: Bubble Tubing® meets chemical and heat resistance standards for water and wastewater applications. It can be used in both fresh water and saline conditions.

Micro-bubble consistency: Designed to produce consistent micro-bubbles, it enhances efficacy across various scenarios.

Performance data: Backed by performance data from controlled and field-scale applications, Bubble Tubing® delivers results.

Some of our bubble curtain solutions

Sound Attenuation Bubble Curtains

View Product

Aeration Bubble Curtains

View Product

Silt & Debris Bubble Barriers

View Product

Water Injection Dredging Bubble Curtains

View Product

Litter & Weed Control Bubble Curtains

View Product

OctoAir® Aeration Systems

View Product

Aerated Reedbeds

View ProductWhat research has gone into Bubble Tubing®?

Highly efficient aeration

During the summer of 2011, the manufacturer of Bubble Tubing® and OctoAir, CanadianPond.ca Products Ltd retained GSEE, Inc., to perform unsteady state clean water shop oxygen transfer tests on ½” & ¾” Bubble Tubing® and the OctoAir-10® aeration systems.

Overall, the results obtained for the CanadianPond.ca Products Ltd. aeration systems were uniformly excellent and produced some of the highest SOTE values GSEE, Inc. has observed.

You can read the research paper here showing the results of Bubble Tubing aeration systems being uniformly excellent and producing some of the highest SOTE values observed.

Silt and sediment pollution mitigation

Swansea University (SEACAMS) studied the effectiveness of bubble curtains in restricting sediment movement in seawater under laboratory conditions on behalf of Frog Environmental. A seawater tank was set up with single, double and triple lines of Bubble Tubing® with sediments of various sizes inserted into the laminar water flow.

Settled sediments were collected on either side of the tubing. A single bubble curtain restricted 50% of silt on average. Overall the study showed that 3 lines of Bubble Tubing® can impede up to 90% of silt dispersal.

Read the research undertaken by Swansea University here.

Underwater sound reduction when piling, dredging, drilling or blasting

A field studies have been undertaken to measure the capacity of a bubble curtain using Bubble Tubing® technology to attenuate underwater sound caused by pile driving, dredging, drilling or blasting.

It has shown that Bubble curtains are effective to reduce dB on all spectrum of frequencies (high to low). The results demonstrated that Bubble Tubing® technology effectively achieves high levels of underwater sound attenuation. On average, the attenuation ranges from 20 dB to 80 dB. Contact us for a copy of this report.

We have also partnered with clients who were early adopters of this innovative technology. Take a look at this project where the bubble curtain achieved a 99% reduction in sound which protected salmon migration seasons during piling operations at a 9 hectare dockyard redevelopment.

Deflecting jellyfish, litter and debris

Testing was carried out with C-Core on behalf of Canadian Pond in measuring the efficiency of Bubble Tubing® in jellyfish mitigation based on tidal currents, jellyfish size, bubble curtain angle, number of curtains and their spacing.

The study demonstrated that bubble curtains are effective at deflecting neutrally buoyant elements such as jellyfish or plastics and organic debris. The research enabled the testing of numerous parameters (angles, air flow etc) in different situations (currents, depths, etc) to identify the best configuration for each situation. This study is available on request.

De-icing performance

Testing has been undertaken to identify the de-icing performance created by Bubble Tubing® linear systems under specific conditions.

The average de-icing rates measured ranged from 3 to 18 mm/h, depending on the measurement location and ambient conditions. De-icing with Bubble Tubing® at low air flow rates is more efficient than at higher air flow rates, resulting in energy savings.

Arming you with the right systems to keep your project on track

For contractors, the challenge of working in or near water is inevitable. But with innovative technologies and solutions like our bubble curtains and barriers, the risks can be managed effectively.

We help companies deliver projects that meet regulatory standards, protect the environment, and keep within budget. Our solutions ensure you’re working with or near water in the smartest possible way. Contact us to discuss your requirements and we’ll create a solution that’s site-specific for your project.

For products, services, training and technical sales support contact us or call 0345 057 4040.

Contact UsDisclaimer: This article is correct at the time of writing and while we endeavour to update annually, legislation may change over time. We pride ourselves on providing site-specific advice. Please contact us about your situation; we’d be delighted to help.