Zero carbon water treatment systems

Managing surface water from construction sites can cause major economic and environmental challenges.

In this article we share how our sustainable and practical zero carbon operation water treatment system can protect rivers and reduce the operational costs and carbon footprint for contractors.

Why can surface water on construction sites cause problems?

- Muddy water is a pollutant and cannot be discharged from a construction site without treatment and an environmental permit, CAR permit or exemption

- Traditional settlement lagoons are not able to separate fine clay particles from water, leading to increased costs for water treatment prior to discharge

- Operating pumps as part of a water treatment system is expensive (see hire costs and fuel example below) and has a high carbon footprint

Our zero carbon silt management solution

We have worked with key partners in the construction industry and developed a zero carbon version of our pumped water treatment system for removing fine clay particles from water.

Our gravity operated silt control systems are a popular choice on construction sites across the UK due to their effectiveness, low product cost and zero carbon operational benefit.

On average our gravity fed water treatment system provides an annual cost saving of over £23,500 and 10 tonnes of CO2 compared with using a pumped system* – potentially saving hundreds of thousands of pounds in hire costs and carbon efficiencies over the course of a project.

Our water treatment systems use Gel Flocculant blocks in conjunction with a Silt Capture Channel to treat clay impacted waters.

Both our pumped (using a Pipe Reactor) and passive treatment systems are modular and scalable, with our basic system having the capacity to treat up to 1,800 litres of muddy water per minute.

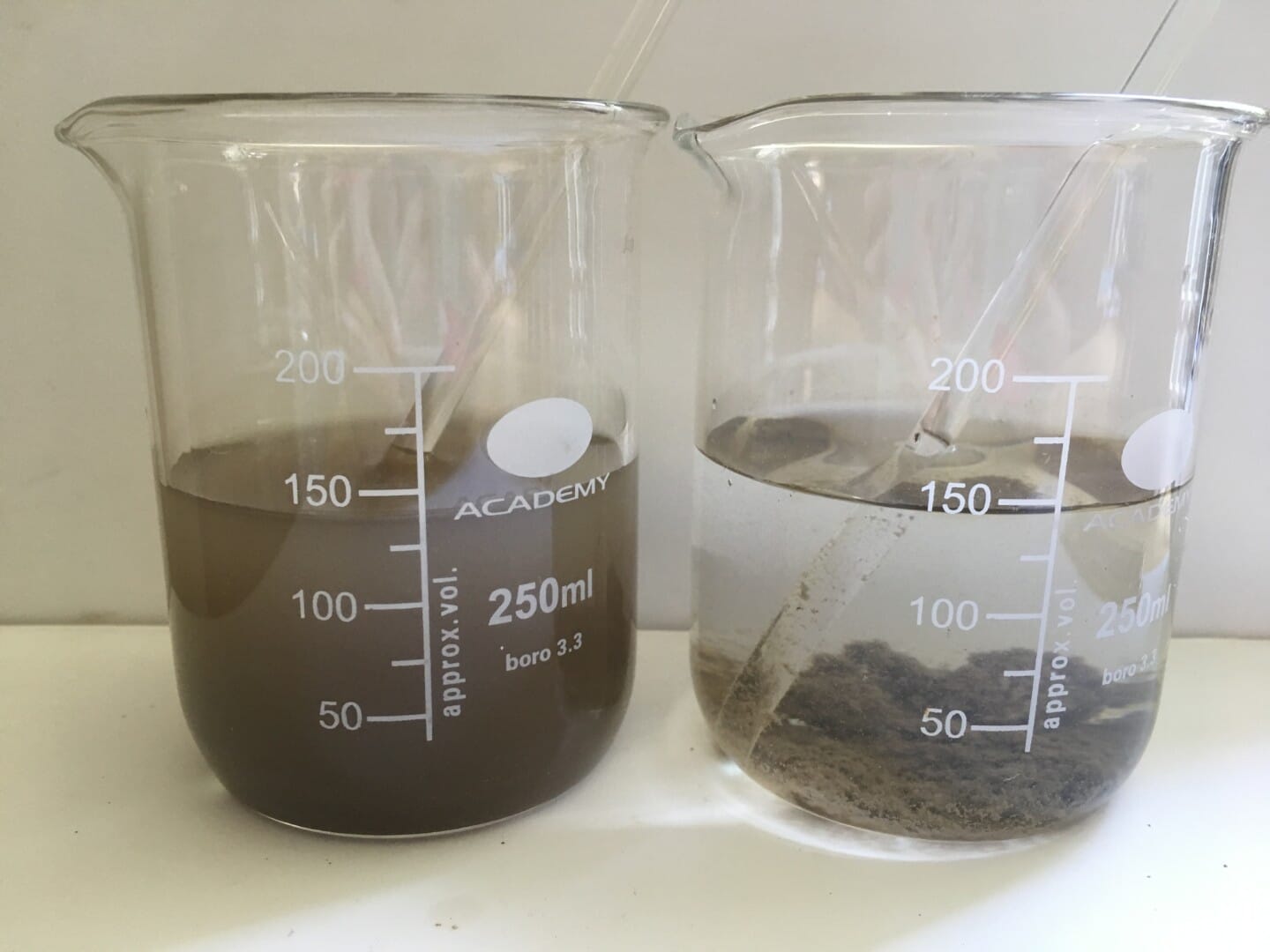

Using flocculant to remove silt from water

Clearflow Gel Flocculant is gaining a reputation across the construction industry for being the most cost-effective method for separating clay particles from water prior to discharge from site.

The treatment process, using Gel Flocculant, is the similar to our pumped system but relies on differential head for the flow of muddy water, eliminating the need for pumps thereby saving money and helping with the project’s sustainable objectives.

The summary table shows a potential annual cost saving of over £23,500 and 10 tonnes of CO2.

Flexible and adaptable approach to treating water using gravity

Site topography can be a limiting factor for the operation of a gravity fed water treatment system, but with early site planning, many contractors already using pumped systems could partly or wholly implement gravity fed systems. This would help reduce a site’s operational costs and carbon footprint.

A further enhancement to consider with the used elements of the Silt Capture Channels, is that with the right permissions, you can dispose of our biodegradable mats by seeding them or leaving them on site to create natural vegetation and habitats.

Passive treatment cost savings for UK construction sites

| Solution | Number of pumps | Pump hire cost (£/Year) | Total fuel (Litres/Year) | Fuel cost (£/Year) | CO2 (Tonnes/year) | Labour |

|---|---|---|---|---|---|---|

| Pumped | 1 | £18,215 | 5,460 | £5,335 | 10.38 | Daily |

| Gravity-fed | 0 | 0 | 0 | 0 | 0 | Weekly |

**Assumptions:

- Cost of 4” pump hire is £350/week

- Each 4” pump is run 8 hours per day, 5 days a week, 52 weeks a year

- 76 litres of fuel per week

- Cost of fuel is £1.35 per litre

- Emission factor of 2.626 kg/CO2 per litre of fuel (UK Government GHG Conversion Factors for Company Reporting)

- Figures are current as of December 2023

Rain Ready®, low carbon site solutions

Supporting the construction industry

As well as supporting the construction industry in protecting watercourses, we focus on providing low carbon solutions, thereby helping the industry achieve its ambitious sustainability objectives. We are the UK & European distributors for the Clearflow Group – and their incredible Gel Flocculant solution.

Early involvement and a more pro-active approach to silt management can save money and improve sustainability performance for contractors, as well as protecting against the risk of fines and prosecution arising from silt pollution.

For further advice on managing silt from construction sites contact us. For quick guidance we have produced a free Silt Control Toolbox Talk, to support improved knowledge and understanding of the issue within the construction industry.

We offer a non-obligatory call or Teams meeting with our Technical Team to talk through your needs at any stage of your project to see where we or our environmentally-friendly product solutions may help.

For products, services, training and technical sales support contact us or call 0345 057 4040.

Contact UsDisclaimer: This article is correct at the time of writing and while we endeavour to update annually, legislation may change over time. We pride ourselves on providing site-specific advice. Please contact us about your situation; we’d be delighted to help.