Mine Water Treatment

Gel Flocculant for Mining & Legacy Sites

Gel Flocculant delivers process driven treatment for mining waters; delivering compliance, efficiency and low whole life cost.

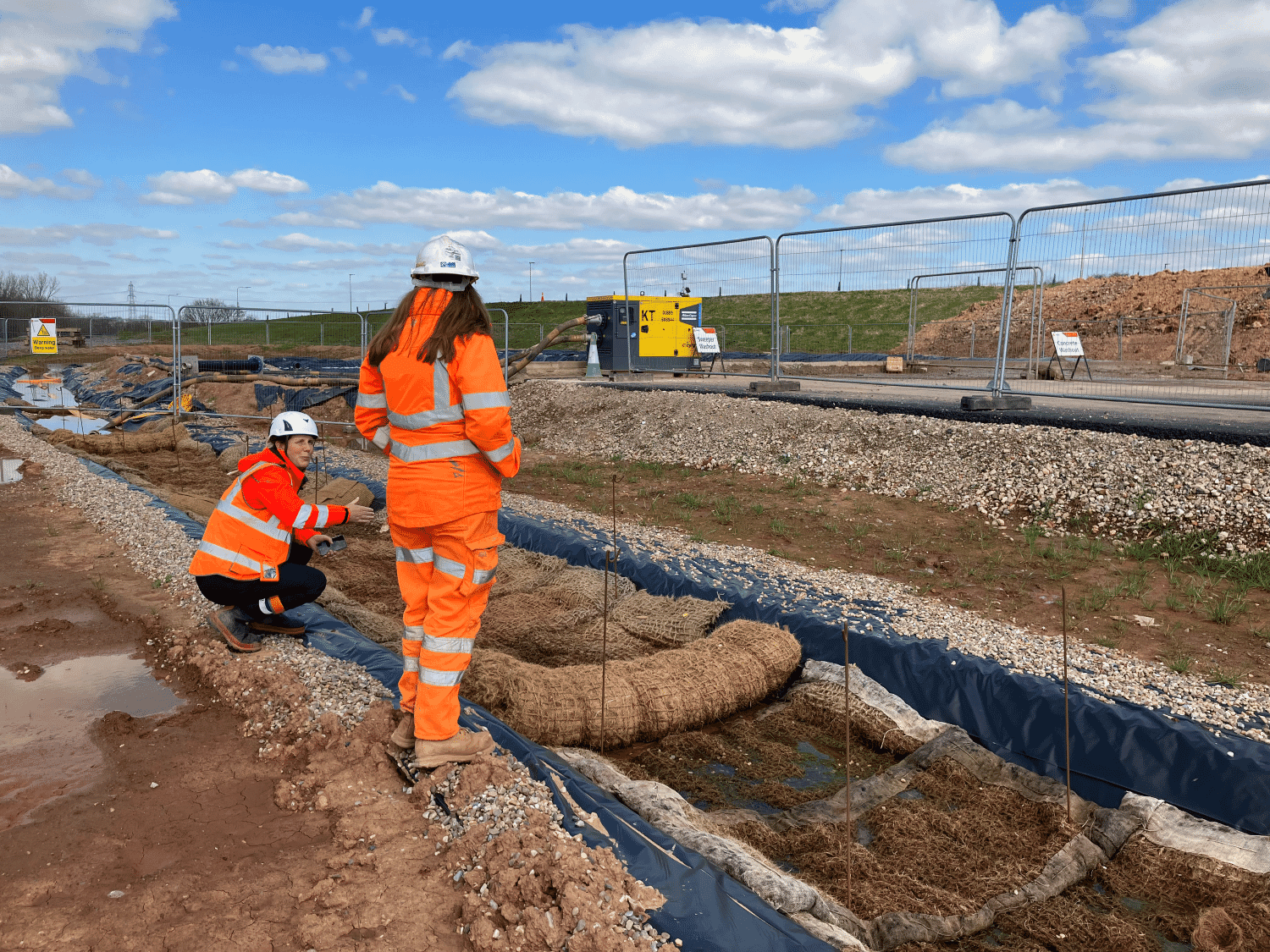

Active and legacy mining sites often generate water that carries fine suspended solids and associated metals.

- Gel Flocculant, deployed via Clearflow GFRs on pumped flows, accelerates settling and capture, supporting clear discharge and water reuse while reducing carbon and operational cost compared with tank-based systems.

- Our technical team specify formulation and dosing through Settlement Testing, ensuring correct application for each site.

Key Benefits

Clearflow’s Gel Flocculant supports the mining sector across the globe

Proven technology

Gel Flocculant added to Clearflow GFR units offer controlled release into pumped flows, improving treatment certainty for variable mine waters

Targets fine solids and associated metals

Rapid clarification reduces turbidity and total suspended solids, supporting compliance limits for mining operations

Whole life value

Compact systems with simple operations and maintenance reduce footprint, labour and cost over project life, compared with tank based treatment

Water reuse potential

Clarified water can be re used for non-potable site needs where appropriate, reducing abstraction and haulage

Technical assurance

Site-specific Settlement Tests determine formulation, dose rate, installation locations and maintenance plans, ensuring correct usage and efficacy

Backed by field results

Multi-reactor deployments at large gold mining projects demonstrate scalability and reliability

Technical specification:

| Form | Dehydrated Gel Flocculant blocks, deployed with patented dosage technology. Multiple formulations available to suit site chemistry and target parameters. |

| Deployment method | Pumped deployment using Clearflow GFR, engineered units that deliver controlled release of Gel Flocculant into pumped streams, followed by settlement and capture. |

| Process control | Settlement Testing underpins dosing calculations, reactor sizing, placement and maintenance planning, enabling consistent outcomes under variable flows. |

| Performance focus | Rapid reduction of turbidity and total suspended solids, with concurrent reduction of particle bound metals and phosphorus, supporting discharge compliance and reuse objectives. |

| Whole life and carbon | Smaller footprint, lower power and simplified O&M compare favourably with tank based systems, supporting carbon and cost reduction objectives over the asset life. |

Installation guides

Videos

Applications

Water treatment

We work with market-leading technology partners to deliver cost-effective solutions for the treatment of water that also minimises carbon impact.

Find out moreMining & legacy mines

Using Clearflow Gel Flocculant™, we offer an innovative approach to safeguard freshwater resources from the impact of both active and historical mining sites.

Find out moreDewatering

Our clever dewatering strategies provide cost-effective and easy-to-implement solutions that ensure site compliance with environmental regulations.

Find out more