Flocculant use on a construction site

This guidance is to assist the construction industry in how and when to use flocculants to prevent site pollution.

What are flocculants and why are they important?

Flocculants are a type of commonly used chemicals that have a wide range of applications in everything from food processing to wastewater and water treatment.

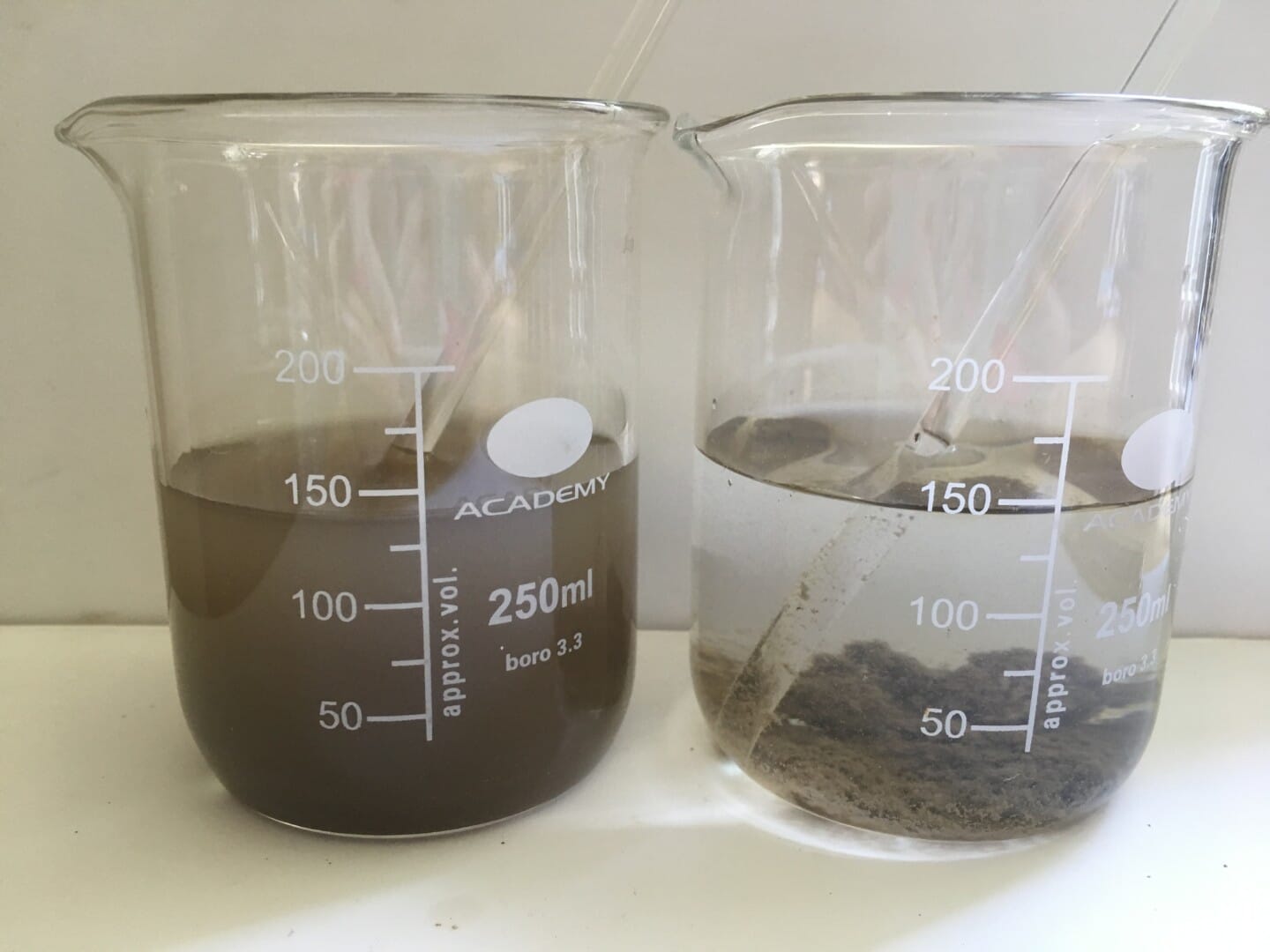

Flocculation refers to the process whereby fine particles are made to clump together into a larger and heavier particle called a ‘floc’. This process is very useful for separating solids from liquids across different industries.

Flocculant is used in the construction industry, often during temporary works, to create ‘flocs’ from very fine particles, such as clays in water.

Creating heavier particles makes the clays easier to settle out of suspension and capture on site. This can play an important role in preventing silt pollution from entering streams and rivers from construction sites.

Flocculants and regulatory bodies

Regulators, such as the Environment Agency (EA), Scottish Environmental Protection Agency (SEPA), Natural Resources Wales (NRW) and Northern Ireland Environment Agency regulate the use of flocculants on construction sites.

This role is important because deploying the wrong type of flocculant or the wrong amount of flocculant can have environmental consequences. Regulators are generally supportive of the use of flocculants, provided means for naturally controlling silt pollution from site have been fully explored and deployments are well managed.

Silt pollution, enforcement action and fines

Construction professionals are becoming more aware of the damage that silt pollution can cause to streams and rivers.

Enforcement actions and fines relating to silt pollution are becoming commonplace and the construction industry is responding by taking the issue of silt pollution more seriously.

Contact UsWhat to consider before using flocculant?

Flocculants can play a crucial role in water treatment by preventing silt pollution escaping from site and into watercourses, however there are several key questions to consider before deploying a flocculant:

- When can a flocculant be used on a construction site?

- What type of flocculant can be used and how are they deployed?

- How much flocculant can be used?

- How can flocculants be used cost effectively to prevent silt pollution?

When can a flocculant be used on a construction site?

With just a little bit of planning, a construction professional can make an assessment as to whether a flocculant is likely to be needed on site at a very early stage in the project.

Gel Flocculant tends to be used in combination with our other silt control products. Activating only on contact with water, the flocculant helps separate soil and silt which can be trapped and captured with Silt Mats or Floc Mats, allowing clean water to be discharged from site. Gel Flocculant can be placed directly into ditches and drains or as part of a gravity fed water treatment system using a Pipe Reactor to control the dosing. The Pipe Reactor can also be attached to a pump if a gravity-fed set up isn’t an option on site.

While we offer a fast service with a quick delivery turnaround we would always recommend being Rain Ready® so that the site is not at risk of causing pollution due to not being prepared ahead of bad weather. Once the rain hits the damage is often done and it could cost a lot more to a business in reputational risk and fines to remediate.

Rain Ready® site solutions

Site assessment and ground investigation can be complex, but for the purposes of understanding whether a flocculant is likely to be needed during temporary works, we can ask the following two questions:

- Will site drainage during construction be connected to ditches, streams, brooks or rivers?

- Will any top soil be removed, exposing a clayey sub-soil during works?

If the answer to both these questions is ‘yes’, it is advisable to engage with environmental support, as your site is likely to be at a higher risk of causing a silt pollution event.

By proactively addressing silt management, construction companies can reduce their vulnerability to pollution incidents, environmental damage, and legal repercussions.

We offer free training on the risks of silt on a construction site and you can download our Silt Control Toolbox Talk to communicate key points to your team. We can also help you understand why your soil structure and particle size is important and offer support around mitigations when looking at SWMPs.

Bringing our water quality and silt control specialist team of consultants on board early allows you to prevent issues arising; through training up your staff, offering technical design and site preparation support, as well as products that are engineered to meet needs across a wide range of industries.

We offer a non-obligatory call or Teams meeting with our Technical Team to talk through your needs at any stage of your project to see where we or our environmentally-friendly product solutions may help.

For products, services, training and technical sales support contact us or call 0345 057 4040.

Contact UsDisclaimer: This article is correct at the time of writing and while we endeavour to update annually, legislation may change over time. We pride ourselves on providing site-specific advice. Please contact us about your situation; we’d be delighted to help.