Involve Frog Environmental early in your silt treatment strategy

Preventing silt pollution and cleaning surface water before discharge can be achieved through preparation and the use of simple interventions on construction sites. Since no two sites are the same, engaging with us early in a construction site project allows our technical team to offer the most effective preventative and reactive solutions, saving clients both money and stress.

At Frog Environmental, we pride ourselves on sharing information and encouraging discussion about non-standard options to find straightforward solutions to common on-site challenges.

Using Gel Flocculant in silt treatment

Gel Flocculant is often used to provide a simple and effective process to treat silt-laden surface water on construction sites.

Its capacity to scale silt treatment sequentially, combined with the ease of use, cost-effectiveness, and adaptability for retrofitting site features, makes it an invaluable tool for tackling silt pollution.

The effectiveness of Clearflow’s Gel Flocculant depends largely on the characteristics of the sediment on site.

How Gel Flocculant reacts to the size, shape and charge of the individual silt particles dictates the type and number of blocks required and number of treatment points.

As part of our service we help you answer these questions.

We start with a settlement test to identify the reactive nature of site samples. This enables us to advise on appropriate treatment measures tailored to suit your site.

Alternatives to large lagoons and settlement tanks

Even the finest silts will settle eventually. The time required to settle these silts without intervention could be days or weeks, which will require unrealistic settlement lagoons to provide adequate settlement times (we are talking impractical lagoons the size of Wembley stadium!).

In combination with the ions naturally found in the water, Gel Flocculant can be used with the flowing water to break down the charge separation between silt particles, creating larger particles that are more likely to settle. Flocculation reduces the time required to settle silt material from days or weeks into seconds.

The main challenge at this stage is that gel flocculation is so effective, it requires careful management of the potentially large quantities of flocculated material produced.

Given a Total Suspended Solids in the waters being treated of 500 mg L-1 (not an unusual value when taking about a pollution event) at a flow rate of 2000 L min-1, the treatment of 1.4 tonnes of flocculated silt will be required every 24 hours (imagine a dumpy bag and a half again).

The silt treatment process

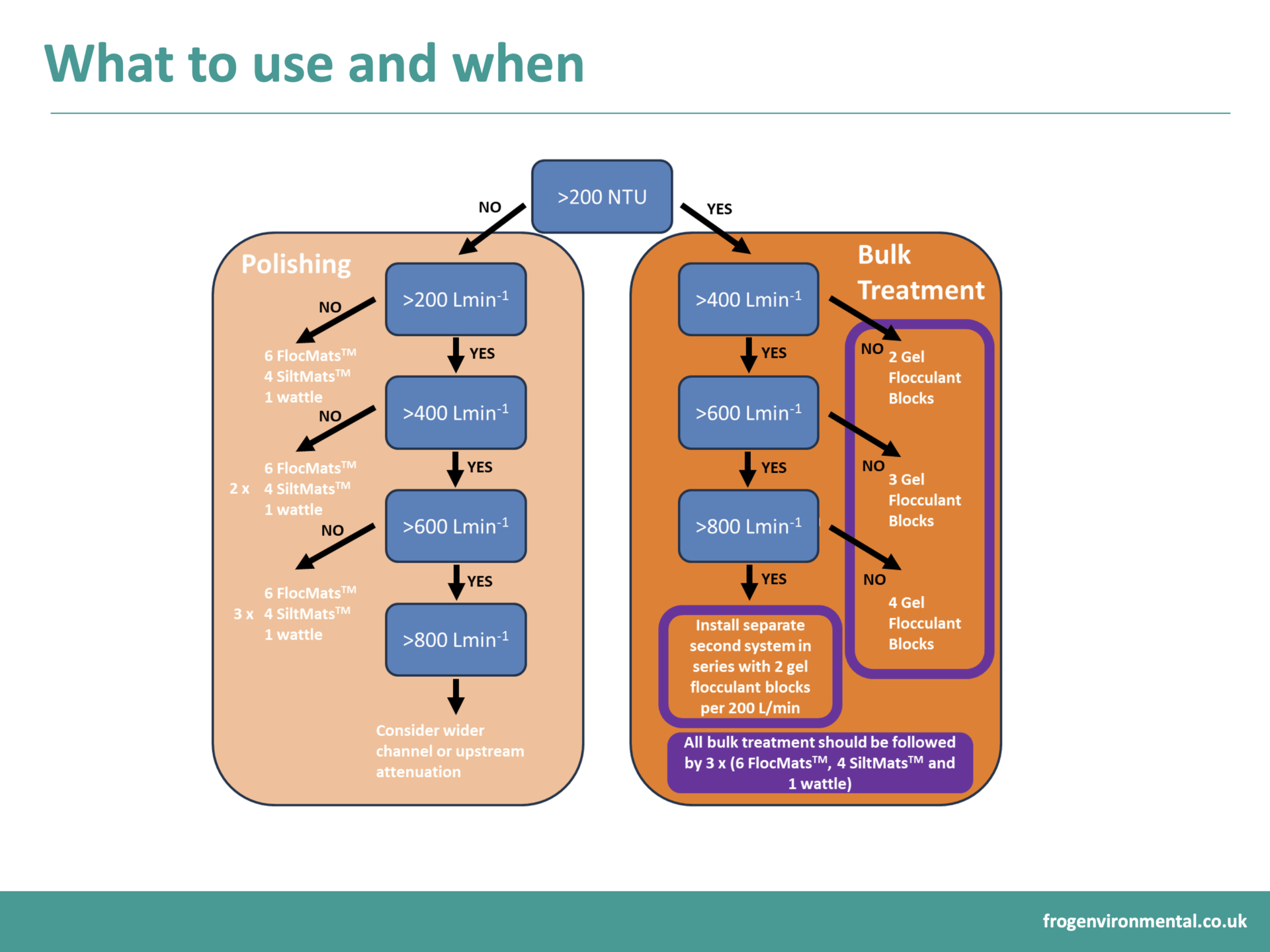

Gel Flocculant treatment can be broken down into two processes, which we refer to as the bulk and polishing phases:

- The bulk process typically uses Gel Flocculant blocks to remove the majority of silt from surface water run off. When pumping dirty water, the procedure involves connecting a Pipe Reactor after the pump with a minimum length of 50m layflat hose. Alternatively gravity can be used to drive the water over the block’s surface and each Gel Flocculant block can treat 200 L min-1. When the reaction is good, treatment can be scaled accordingly. When using a bulk procedure a small fraction of fine silt particles won’t be captured by this process. This is why a polishing procedure is employed following any bulk treatment.

- Following a bulk process or where there are lower concentrations of silt which does not need bulk treatment first, a polishing procedure can be employed. A Polishing Channel is based on a combination of 3 * Floc MatsR and 3 * Silt MatsTM. We also use a Silt Wattle to help slow the flow of water as it passes over the treatment mats.

These processes are important. We have spent years carrying out research and development and field testing to fine-tune our approach to deliver you simple silt treatment solutions.

Remember, for Gel Flocculant to work it requires physical mixing – as long as you have flowing water moving over the block’s surface you can adapt Gel Flocculant to resolve most site silt treatment issues.

Putting Gel Flocculant in ponds or stationary water doesn’t work. Gel Flocculants do not dissolve like sugar in tea. Instead, the process requires a delicate balance: enough energy to mix the flocculants, followed by minimal energy to allow settling.

Another important aspect of our service is our carry-over calculations. These calculations determine the maximum number of Gel Flocculant blocks you can use while staying within UK environmental standards. They are based on conservative parameters, assuming the Gel Flocculant is released in a very short time into distilled water, to estimate how much of the composition could leave the site.

Despite the unlikely nature of these conditions, we adhere to drinking water standards for any water released from the site, which are stricter than environmental standards. The only exception is mine wastewater, which reacts differently, although we have achieved excellent results in this area as well but require different flow rate considerations.

For further information on how we can help you with your site or questions about the Clearflow Gel Flocculant more generally, please feel free to get in touch.

As leaders in silt control, we offer a non-obligatory call or Teams meeting with our technical team to talk through your needs at any stage of your project and see where we or our environmentally-friendly product solutions and technical expertise may help.

Frog Environmental are silt control and water quality specialists working with contractors, regulators and consultants within construction, utilities, marine and coastal and public sector industries across the UK and Europe.

Our silt management products and systems are designed to prevent silt pollution incidents on construction sites throughout the UK. With years of dedicated research, we provide industry-leading solutions that ensure compliance and best practices.

Follow our news and updates, find out more about our products, or contact us for technical support.