With the ongoing growth of the construction industry and unprecedented wet weather, effective flood risk management has become increasingly important. Knowing your soil and silt particle size is key to success.

Surface Water Management Plans (SWMPs) on construction sites play a significant role in safeguarding against surface water flooding and the potential for silt pollution and siltation of waterways.

At Frog Environmental, we offer a range of silt control CPD courses emphasising the importance of understanding SWMPs and have developed a range of products to address the challenges of silt pollution and siltation.

Involving us early in the project process saves money and time.

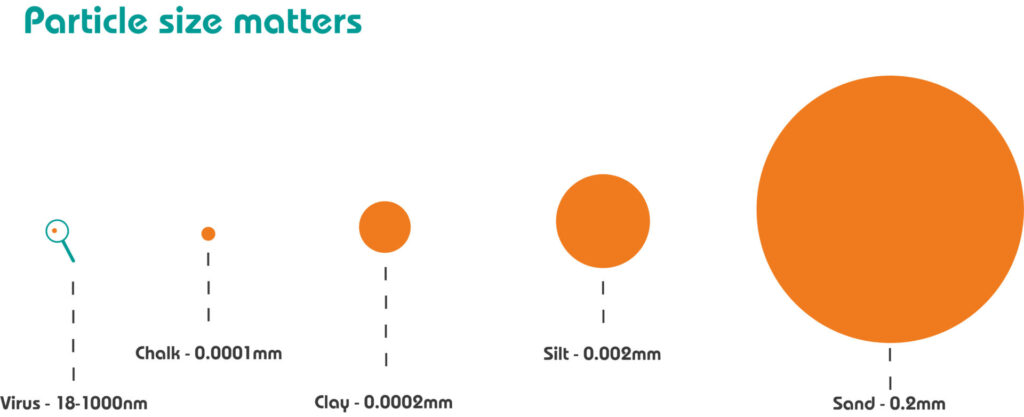

But why does silt particle size matter?

Understanding silt particle size: The hidden variable.

The subsoil connection:

Beneath the surface lies a complex network of soil particles, ranging from fine silt to coarse sand.

The subsoil acts like a sponge, absorbing and releasing water. Particle size directly influences how quickly water infiltrates or drains through the soil.

Risk assessment:

SWMPs assess flood risk by considering a variety of factors, including particle size.

Fine-grained soils (such as clay) retain water, leading to slower drainage. Coarse-grained soils (like sand) allow water to flow more freely.

Overlooking particle size in SWMPs can lead to misjudging the risk level, with potentially damaging consequences. Causing potential silt pollution and siltation off-site.

Mitigation strategies: Aligning reality with plans.

Infiltration vs. runoff:

- SWMPs propose strategies like permeable surfaces, green roofs, and swales to manage surface water or our herringbone system which uses various products to trap these fine particles.

- Particle size significantly affects infiltration rates. Fine particles hinder water movement, while coarse particles enhance it.

- Ignoring particle size can result in mitigation measures falling short or overshooting the mark.

Treatment challenges:

SWMPs address water quality. Treatment facilities (e

.g., Pipe Reactors, linear silt management ditches) handle pollutants before discharge.Particle size matters here too. Fine particles carry more contaminants, requiring specific treatment approaches. Our technical expertise can assist in analysing this.

Misalignment between particle size and treatment capacity poses environmental risks.

The ripple effect: Real-world implications.

Construction sites:

- Large construction sites are hotspots for surface water runoff.

- Neglecting particle size can lead to clogged drainage systems and localised flooding.

- SWMPs must consider soil characteristics for site-specific solutions.

Key takeaways:

- Particle size within the subsoil directly impacts surface water management planning effectiveness.

- SWMPs must consider both infiltration and treatment aspects.

- Ensure plans align with reality – particle by particle!

As well as advising on effective silt management strategies on site, we can help construction sites with settlement testing to determine particle size and make up to establish the risk of silt pollution from a site. It also helps us to advise you on the best form of water treatment to control silty water. We offer a no-obligation initial call or meeting; contact us for support.

Frog Environmental is a leading UK specialist in silt management, dedicated to helping construction companies minimise their risk of pollution.

We bring innovation to the market through a range of cutting-edge products backed with our technical team’s knowledge, and strive to create new benchmarks for environmental protection, client efficiency, value and sustainability.

Follow our news and updates, find out more about our products, or contact us for technical support.