Bringing innovation to ditches on construction sites to trap and manage silt

Frog Environmental uses interceptor ditches to design passive, low carbon, rain-ready silt management systems for linear construction sites to prevent pollution.

By their nature linear construction sites involving railway lines, roads and pipe lines often have a constrained or restricted footprint. The topography tends to be challenging with narrow boundaries stretching vast distances.

On these types of sites there is usually little room for attenuation ponds or settlement features to help manage silty water during construction work.

Zero energy systems that respond to rain

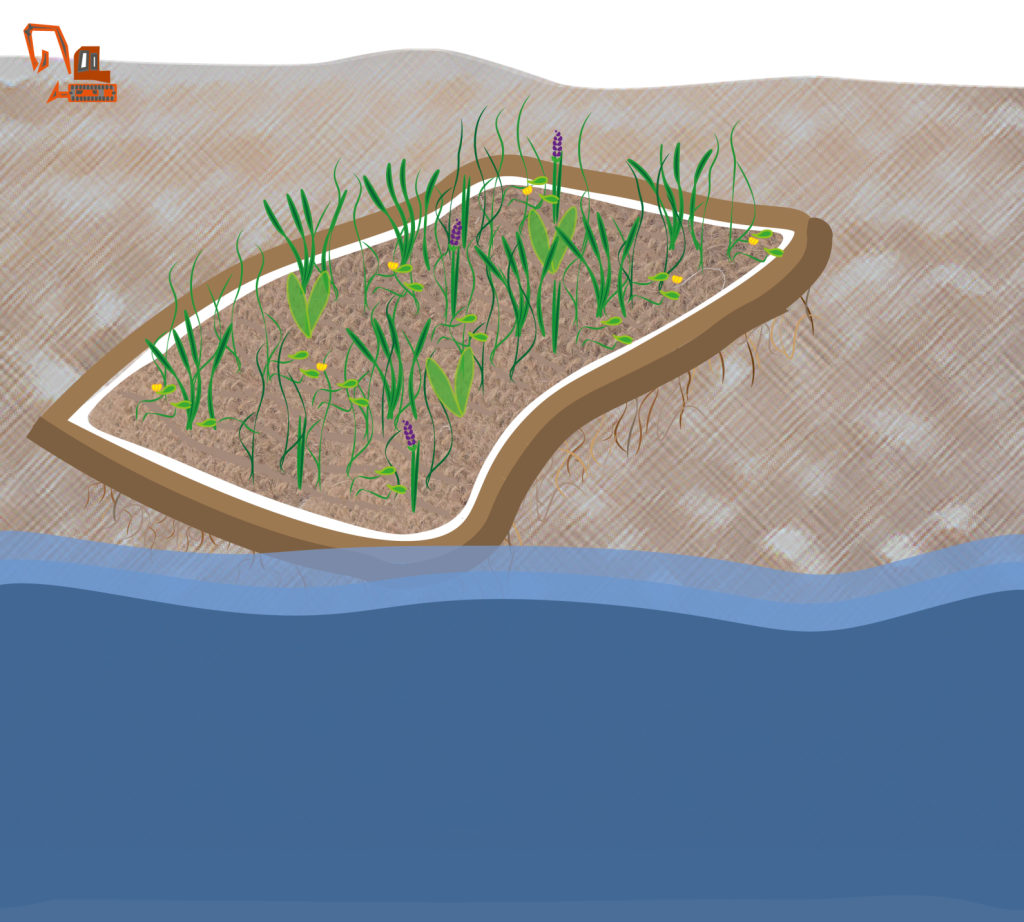

Frog Environmental’s innovative approach prevents erosion by controlling the water flow on site, focussing it into managed ditches containing Silt MatTM, Floc MatsTM Rock Checks and Silt Wattles that help slow the flow of the water and remove sediment from the water.

These systems are passive and require no energy to run. They can be put in place ahead of rain to protect sites from silt pollution at any time of year.

We use other gravity-fed rain-ready products to enhance sediment separation from water such as Gel Flocculant placed in pipes located in ditches. This technique binds solids together which drop out of suspension.

Rain activates these systems and the products require minimal maintenance, however monitoring is recommended as part of your water management plan.

Retain soils on site, release clear water from site

As dirty water moves along a ditch, we want to be able to transfer those solids into a state where they can settle, allowing us to trap them or separate them out. This then leaves us with clear water that is safe to emit into rivers, streams or other watercourses.

When working in these environments we need to think about where we are using water, and how we stop it from running off-site, where it could cause harm to the environment or flood neighbouring land.

We aim to move clear water off site and retain the silt and sediment onsite.

Innovative approaches to treating water on sites constrained by size

We are leading the way in capturing and treating site water by using interceptor ditches when there is limited capacity to store water within the site boundary. We are further developing these processes for non-linear situations, saving space on other constrained sites and enhancing the performance on attenuation ponds or lagoons.

We are creating new, innovative techniques such as using smaller interceptor features, called catch pits, which we use at frequent intervals along a ditch.

Frog Environmental has developed novel techniques to slow the water down, treating it with Gel Flocculant, which causes the sediment to accrete, and then dropping it out into the ditch or onto a Silt Mat or Floc Mat.

We also help you understand your soil structure and make up. Understanding the particle size of your silts is very important when writing your Surface Water Management Plans.

Reusing Floc Mats and Silt Mats as erosion control on site

The biodegradable silt mats will silt up over time, at which point they can be replaced, and the silt-laden ones can be used to protect exposed soils elsewhere on-site by pinning or laying them out.

They can be seeded, or if left they will vegetate naturally, whilst protecting the soil from erosion. They can also be used around hedgerow or tree planting as biodegradable, moisture-retaining and weed suppression.

Incorporating this as part of a materials management plan that considers waste regulations will meet compliance and provide an excellent way to retain the nutrient-rich soil on site.

Attenuation ponds versus linear ditch systems?

We would always prefer to design in attenuation ponds because they create capacity in the system to cope with the spikes in water flow. But there are times when we do not have the ideal situation and are working within physical constraints, this is where we become more creative.

We recommend early consideration in the project to understand each dynamic phase, for example, exploring how the site topography will change so that we can create a plan to allow for this.

Low carbon, passive solution

These low-carbon systems evolve with the changes in the site. This helps us resolve many issues which could be costly if not anticipated and dealt with at each stage. It also avoids the use of pumps, meaning that the energy use in the project is zero, and the system is always ready to go whether you are on-site or not.

Leela O’Dea, director at Frog Environmental, spoke at the IECA conference, in Spokane, Washington in February 2024.

Working with you

To support our clients most effectively it is helpful for us to be involved as early in the project as possible.

The sooner we are involved the earlier we can put in silt interventions that will save significant amounts of money, whilst working out whether the project is a low-risk water management project or an elevated risk one; either way, forward planning reduces costs in the short and long term.

At the start of the project, we work on:

- Understanding the topography of the site

- Understanding how that topography will change over the course of the project

- Understanding the soils

- Getting involved at the archeology stage, if possible, to prevent unnecessary exposure of soils and to immediately prevent early pollution and erosion risks

- Understanding the catchment of the area to create the water exit plan

- Putting in place a water management plan that adapts to the lifetime of your project

- Planning how we will turn dirty water clear and take it off site

- Whether Silt MatsTM or Floc MatsTM can be used on site as further long-term erosion control and reducing off site waste as a part of the Materials Management Plan

Leela O’Dea Technical Director explains managing silt using interceptor ditches

Watch on our YouTube channel.